Determination of Selected Detergent Residues in Lanolin by HPLC

Dr. Mehmet Cetinkaya

Labor für Rückstandsanalytik Bremen GmbH

Anne-Conway-Straße 9

D-28359 Bremen

www.lr-bremen.de

Dr. Wolfgang Parmentier

Deutsche Lanolin Gesellschaft

Summary

A test procedure was developed in order to determine the detergent residues of alkyl phenols and alkylphenol ethoxylates in lanolin. After the extraction with 2-propanol, the detergent residues in lanolin were quantified by HPLC/DAD or FLD, and confirmed by GC-MSD. The amounts of alkylphenol ethoxylates found are less than 0.01-0.91 weight % in raw wool wax, and 0.03-0.06 weight % in lanolin.

Introduction

In some countries outside of the EU nonylphenylethoxylates are used as cleaning agents in the production of lanolin. Due to this, a small amount of detergent residues is also contained in raw wool wax. As detergents of this type are strong O/W emulsifiers, they tend to obstruct the important natural W/O emulsification power of raw wool wax and lanolin. They can additionally affect their dermatological properties.

It is therefore important to determine these detergent residues in lanolin, and to remove them.

The presence of these residues also raises health concerns, as they have estrogenic effects.

The determination of alkylphenolethoxylates in washing and cleaning agents by HPLC/FLD (1), in sewage by HPLC/UV and GC/MSD (2), as well as in lanolin by gravimetric analysis (3) has already been documented.

The goal of this study is to determine whether remains of detergent residues are present in raw wool wax and lanolin, and to develop a testing method, which can be routinely implemented.

Area of Application

Testing Parameters

Reagents

Devices

1. Preparation of sample

2. HPLC determination with DAD

2.1 HPLC measuring conditions

2.2 Chromatography conditions (Fig. 2)

The method is designed for the routine determination of selected detergent residues in lanolin and in raw wool wax. The detection limit is 0.01 weight %.

Detergent residues: alkylphenol- and alkylphenolethoxylates

4-nonylphenol

4-oetylphenol

4-nonylphenolethoxylates (mono-, di-)

4-oetylphenolethoxylates (mono-, di-)

2-propanol

Acetonitrile

Water

Ammonium acetate

Standard substances from Fa. Dr. Ehrensdorfer GmbH

Ultrasound bath

Drying cupboard

Reagent glasses

Measuring cylinder

Thermometer

Pasteur pipettes

pH-meter

HPLC with DAD (diode array detector) and FLD (fluorescence detector)

Gas chromatograph with MSD (mass selective detector)

Procedure

1 g of lanolin is weighed out, absorbed in 10 ml 2-propanol, dissolved at 50-60 °C water bath temperature, homogenized, and left to stand at room temperature for 15 minutes. Then the 2-propanol extract is filtered with a membrane filter and analysed using HPLC with DAD or FLD and with GC-MSD.

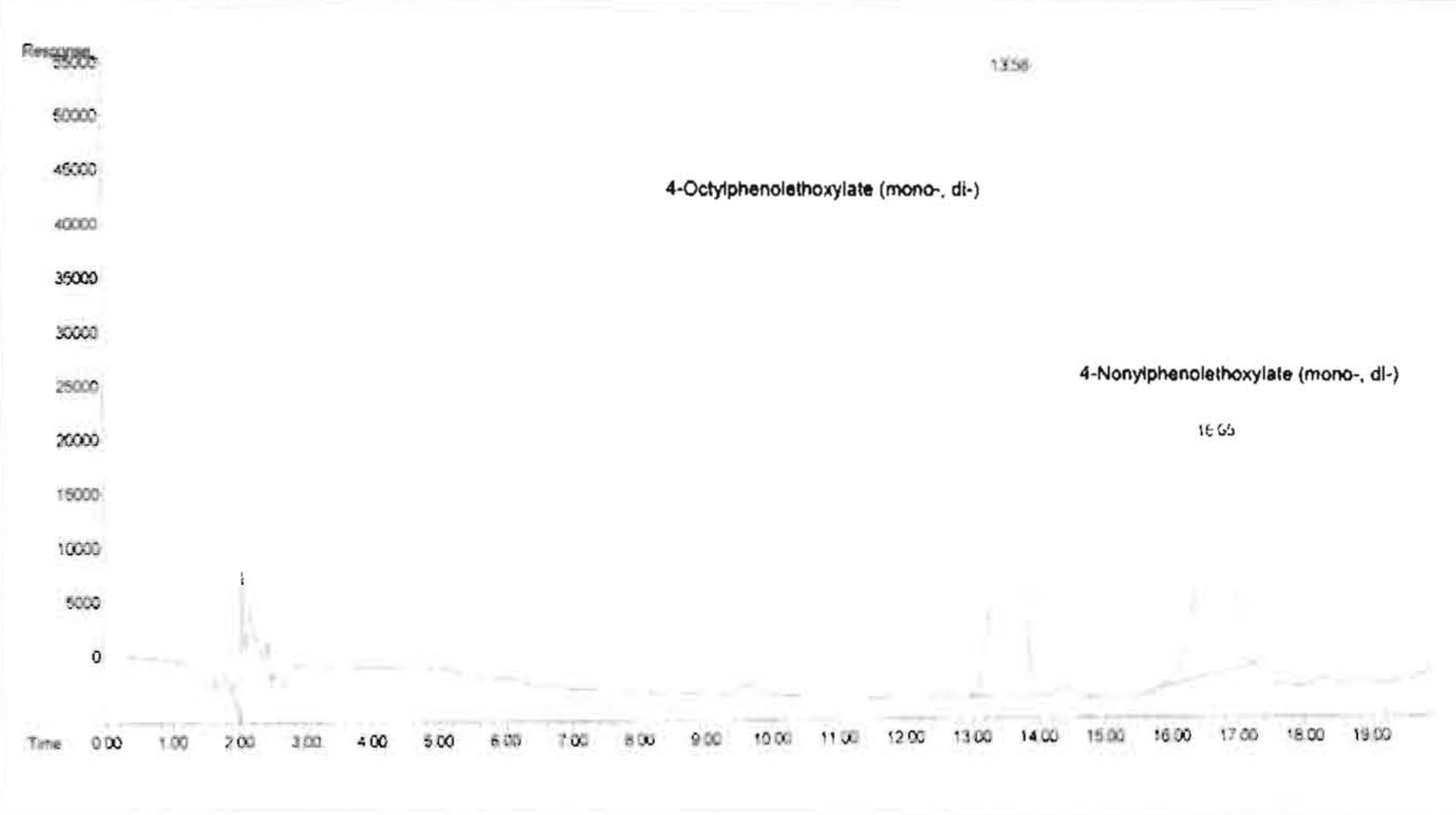

Fig 1. HPLC chromatogram of the standard solutions. Chromatograpy conditions according to 2.2. Standard solution concentration 100 mg/l methanol.

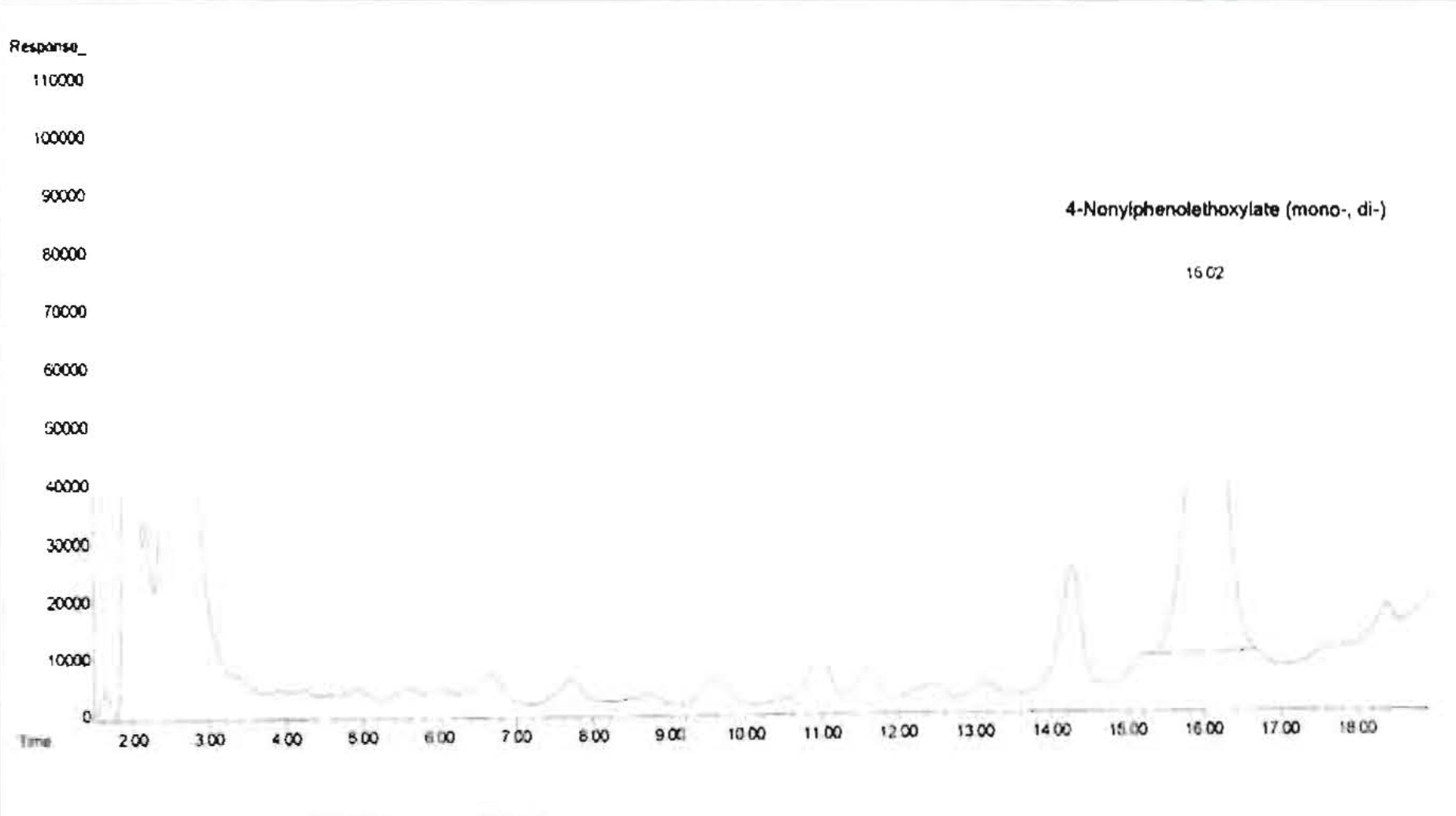

Fig 2. HPLC chromatogramm of a lanolin sampie. Chromatography conditions

according to 2.2.

The sample extracts are determined by HPLC with DAD or FLD as described above. Under the HPLC-measuring conditions, the residues elute with the same alkyl rest independently of the degree of ethoxylation in a single peak (Fig. 1).

Due to the alkyl rest's aromaticity, UV or fluorescence detection is possible. Care should be taken that in all quantitative measurements, the signals lie in the detector's linear operating range.

Column oven: Mistral Spark Holland

Automatic sample loader: Merck-Hitachi model AS-2000

Pump: Merck-Hitachi L-6200

Detector: HP Series 1100 DAD

Analytic system: HP Chemstation

Column: LiChrospher 100 RP-18 (5µm)

Detector: DAD 280 nm

Flow rate: 1.0 ml/min

Oven temperature: 40 °C

Dose volume: 25 µl

Fluxing agent A: acetonitrile, B: ammonium acetate 0.05 M

Gradient programme:

| time [min] | A [%] | B [%] |

| 00 | 55 | 45 |

| 01 | 55 | 45 |

| 13 | 80 | 20 |

| 17 | 100 | 0 |

| 35 | 100 | 0 |

| 45 | 55 | 45 |

3. Gas chromatographic determination by MSD

For the determination of detergent residues, gas chromatography using MSD is used. In contrast to the determination by HPLC-DAD, the GC-MSD method enables a better separation of detergents according to their alkyl and ethoxylate chain length. Furthermore, this method is more selective and more sensitive. However, the samples need to be thoroughly cleansed.

3.1. Measuring conditions

Agilent gas chromatograph 6890 N with MSD 5973 N

Separation column: Fused Silica capillary column DB-5 MS, 30 m, 0.32 mm ID

Film thickness 0.25 µm

Carrier gas: helium 5.0

Detection: mass-selective detector

Injection volume: 2 µl

Injector system: Split

Type of ionisation: EI

Temperature programme:

Injection temperature: 250 °C

Detector temperature: 300 °C

Column temperature: 150 °C (1 min), 150 °C to 250 °C (10 °C/min) 20 min

Analysis

Identification and calibration

The residues are identified and quantified by comparing the retention time of

the sample's detector signal with the

standard substances.

The quantitative determination by HPLC

is done with the analytic system HP

Chemstation by comparing the peak areas of the solutions to be analysed with

those of the standard solutions. The blank value can be calculated via the total procedure. Care should be taken that in all quantitative measurements, the signals lie in the detector's linear operating range. The linear operating range is determined by at least five points of different concentrations. It lies between 0.01-0.5 weight %.

Calculating the amount of residue

The amount of detergent residue in lanolin is calculated according tot he following formula:

| R = |

A x B x C ------------------ D x E |

R = detergent amount in weight % A = area of the sample solution B = concentration oft he standard solution in weight % C = final volume oft he sample in ml D = area value oft he standard solution in weight % E = initial weight of the analysis sample in g

|

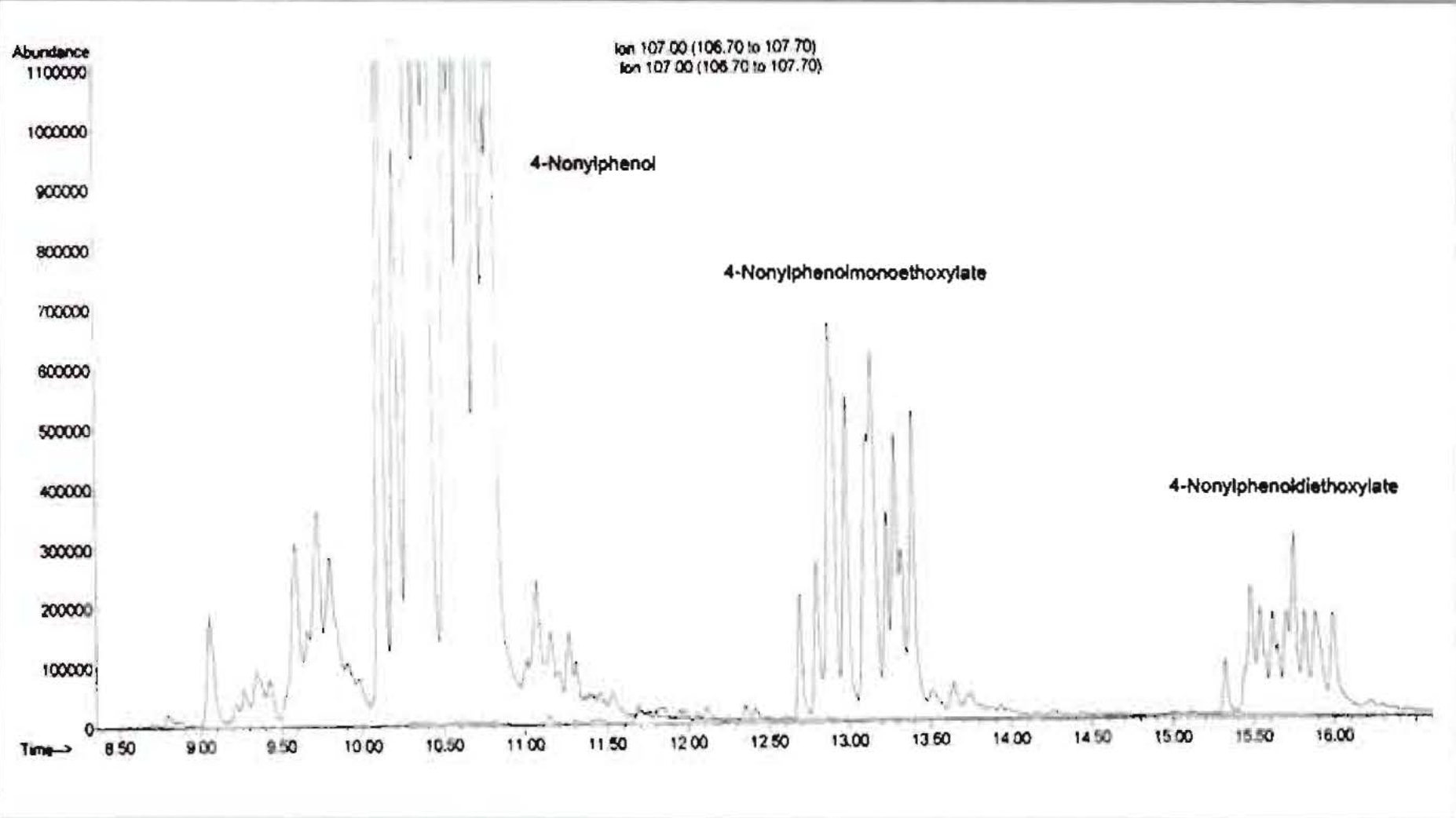

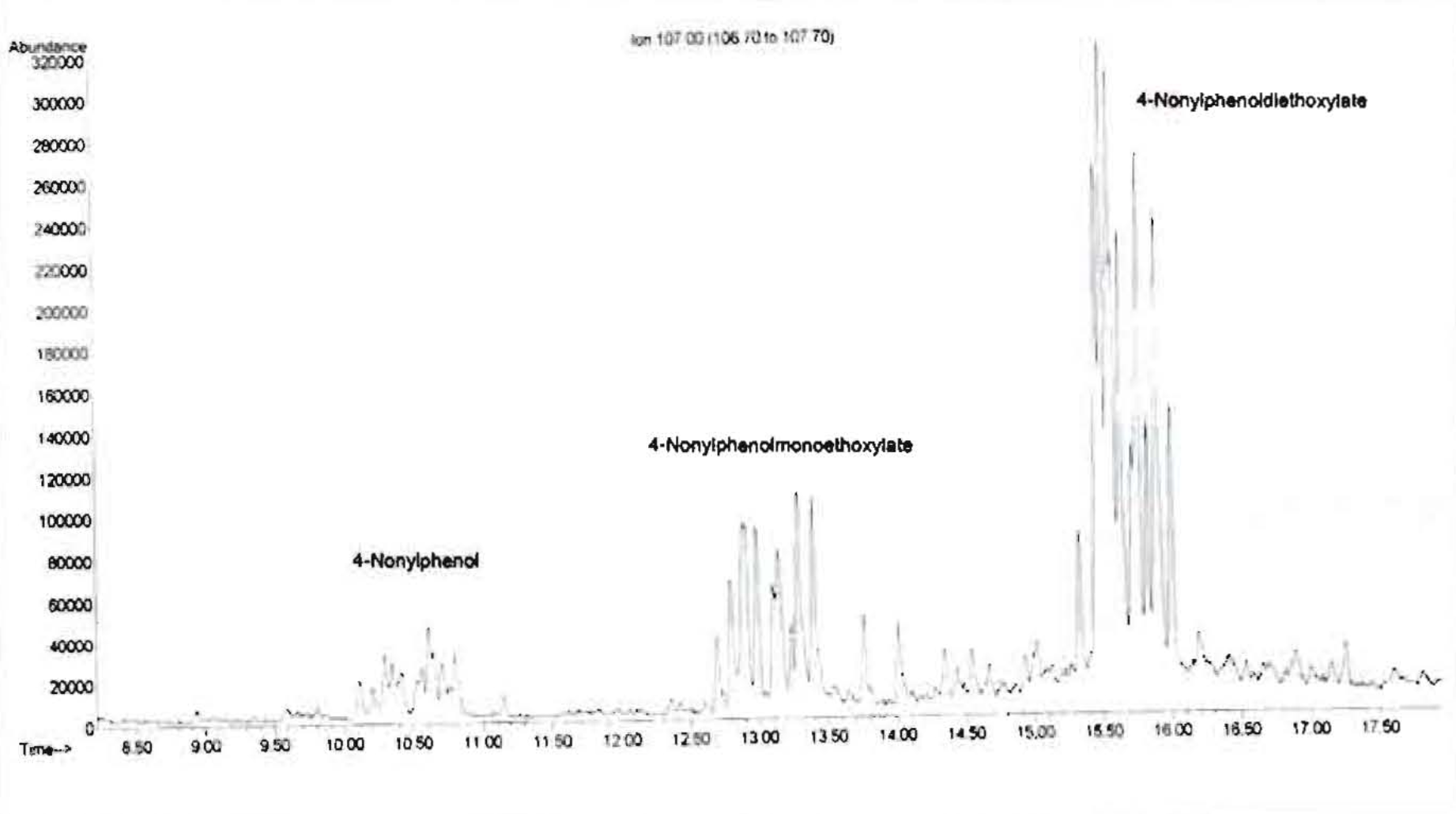

| Fig 3. Mass spectrum of the standard solutions. Measuring conditiions according to 3.1. Concentration of the standard solutions 100 mg/ml methanol each. |

|

| Fig 4. Mass spectrum of a lanolin sampie. Measuring conditiions according to 3.1. |

Results and Discussion

The recovery rates were determined in additional tests, in which defined amounts of detergent residues were added to lanolin samples. The hereby established recovery rates are listed in Table 1.

The optimal reduction of detergent residues is achieved by repeated extraction with 2-prapanol (Table 2).

The gas chromatographic determination with a mass selective detector enabled us to detect short chained nonylphenolethoxylates with low ethoxylation grades (mono-, di-) in raw wool wax and lanolin patterns. This suggests that the used detergents are decomposed during the extraction of raw wool wax. Nonylphenolmonoethoxylate and nonylphenoldiethoxylate are important by-products of nonylphenolethoxylates (Fig. 3 and 4).

4-nonylphenol, 4-octylphenol and 4-octyl phenolethoxylates (mono-, di-) were not detectable (Table 3 and 4).

Tested lanolin samples from different EU- countries contain 4-nonylphenolethoxylates (mono-, di-) in quantities below the legal limit value (4) of 0.1 weight % (Table 4).

|

||||||||||||||||||||||||||||

|

|||||||||||||||

|

|||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||

Literature

(1) Bestimmung von Alkylphenolethoxylaten mittels HPLC, Länderbeauftragte für den Vollzug des Wasch- und Reinigunsmitteigesetzes, December. 2003

(2) Sprengler Peter, Identifizierung und Quantifizierung von Verbindungen mit östrogener Wirkung im Abwasser, PhD Thesis, Stuttgart University, 2001

(3) NK Chemicals Pte Ltd, QC Standard analytical Method 1996

(4) Bundesgesetzblatt Teil I Nr. 9, Achte Verordnung zur Änderung Chemikalienrechtlicher Verordnungen vom 25. Februar 2004